Modern packaging design has changed rapidly. Today, brands need more than just good-looking boxes. They expect packaging that supports branding, sustainability, faster production, customization, and cost control—all at the same time.

But traditional manufacturing methods can’t keep up.

After working closely with packaging manufacturers, converters, and print businesses, I see the same pattern everywhere. Old production models struggle with customization, shorter print runs, and even simple branded add-ons like custom packaging tape. Analog workflows are too rigid for the speed and flexibility today’s market demands.

This is where our web to pack solution steps in. It helps businesses rethink how custom packaging is designed, managed, and produced at scale. It connects modern digital buying behavior with the realities of physical manufacturing through a single platform that streamlines every stage of the design process.

In this blog, I will break down the pressure that has shaped today’s product design landscape, the operational challenges the printing industry faced along with that, and how smart AI-powered web to pack software can help your packaging business overcome them.

Why the Packaging Industry Is Under Pressure

The packaging industry is expanding rapidly yet becoming dramatically more complex at the same time. This contradiction between growth and success is the biggest reason many printers and converters are struggling operationally.

Customization Needs Have Exploded

Brands are asking for far more customized packaging than ever before.

A single FMCG or beverage brand may handle 200+ SKUs, each with different sizes, artwork, languages, or regulatory details. Seasonal editions, influencer packs, and regional versions add even more work to the design and production pipeline.

Traditional systems were built for long, predictable runs, not hundreds of small variations with custom sizes and unique dimensions.

Every new SKU means more artwork changes, more setup time, and more room for errors. This makes it hard for printers to keep up, especially when customers expect fast delivery and frequent updates. The web to pack technology addresses this by allowing users to create and customize packaging products in real time through an intuitive online store interface.

Design Refresh Cycles Are Much Faster

Packaging designs no longer stay the same for years. Earlier, a brand would refresh its packaging every 5-7 years.

Today, most large brands change artwork every 12–18 months, and some run quarterly updates for promotions or limited editions. Each update needs new artwork checks, proofs, approvals, and production adjustments through a streamlined packaging workflow.

Traditional printing workflows struggle with this speed because they rely on slow setup processes and longer runs. The more frequent the changes, the more downtime, waste, and delays the business faces. Modern web to print solutions help businesses save time and manage these rapid design cycles more effectively.

Scale Custom Packaging Without Chaos

Easily handle growing order volumes, new packaging SKUs, and customer demands without increasing operational complexity with our web to pack software.

Sustainability Regulations Are Getting Stricter

Sustainable packaging printing is no longer optional. The market was worth $272.93B in 2023 and is growing at 7.6% a year, driven by new global laws and eco-conscious customers.

Regulations like the EU’s PPWR and rising plastic taxes push brands to use recyclable materials, reduce waste, and avoid unnecessary packaging. Companies must review their processes carefully to ensure compliance and reduce costs.

The problem is that traditional bulk printing works the opposite way—companies often print thousands of extra units just in case. This approach doesn’t suit modern brand requirements or market expectations.

Consumers now compare traditional plastic packaging with eco-friendly alternatives, driving brands toward responsible packaging choices. Smart businesses produce what they need, reducing material waste and helping projects stay within budget.

E-Commerce Wants Speed – Measured in Days, Not Weeks

E-commerce has completely changed the pace of packaging production, creating new opportunities for businesses that can adapt quickly.

DTC brands frequently launch their products and anticipate packaging delivery within 7–10 days of artwork approval. Packaging order sizes are smaller—often 500 to 5,000 units—and many require personalized versions with custom graphics and spot colors.

They also prefer packaging that is lightweight, right-sized, and shipping-friendly. Traditional printing, designed for 50,000+ unit runs, cannot meet these expectations.

The bottleneck often lies in artwork handling, quoting, and prepress—even when digital presses are available. The solution lies in adopting web to pack platforms that can manage high-speed workflows and deliver print-ready files faster.

And ultimately…

All these pressures highlight one main problem: the old bulk printing model does not fit today’s market.

Extra inventory often turns into waste when designs change. And slow workflows lead to missed deadlines. The industry’s real challenge is not demand—it’s outdated processes that no longer match how customers buy packaging today.

Web to pack technology bridges this gap by creating a compatible system that works seamlessly across design, production, and fulfillment.

The Major Challenges Packaging Businesses Face

These are the real-world challenges I repeatedly encounter across packaging production environments. They are the silent killers of profitability in traditional workflows.

Web to pack software restructures the entire package printing workflow. It integrates online ordering, design automation, prepress validation, and production readiness into one system that users can access from a single platform.

Also Read: Which are the major challenges in offering custom size and personalized packaging products online?

Dead Stock Due to Frequent Design Changes

Modern product packaging changes often due to regulatory updates, promotional branding, or language localization.

A simple change in ingredients lists or legal text renders old packaging unusable. When packaging is produced in bulk, any design update instantly turns large volumes of inventory into financial liability.

Companies are forced to pay for warehousing boxes they will never use. Eventually, they must pay again to have that dead stock destroyed. This use case demonstrates why agile production matters.

Solution

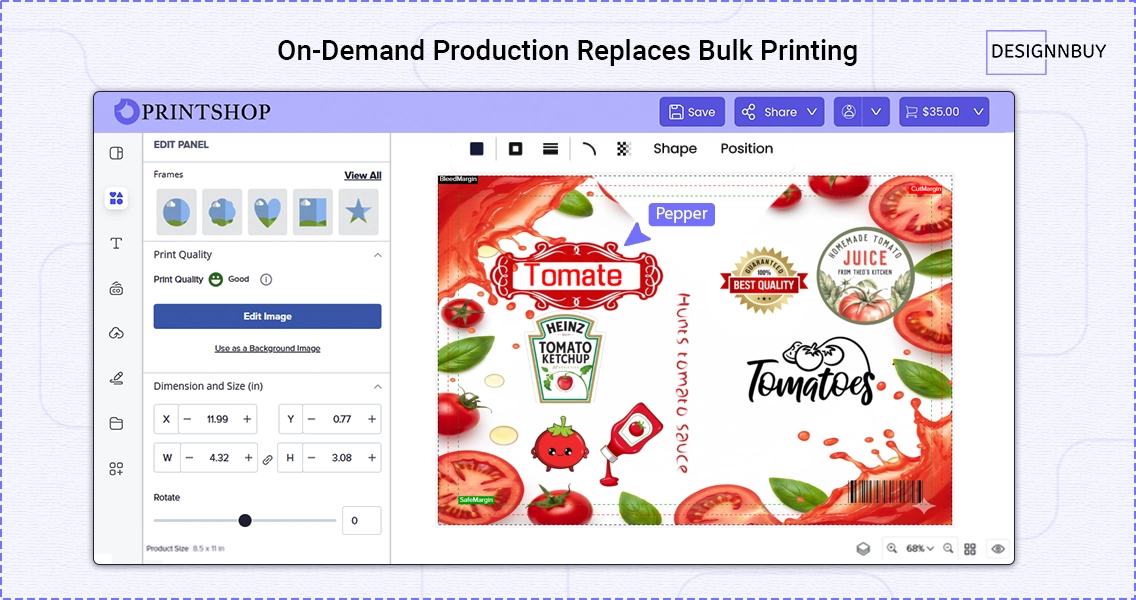

With online packaging enabled by our web to pack solution, products are produced only when packaging orders are placed. This shifts the traditional model from “make-then-sell” to a more efficient “sell-then-make” approach.

This approach eliminates speculative bulk production entirely. You no longer have to guess how many boxes or cartons you might need based on projected quantity. It enables true on-demand manufacturing that matches real-time demand.

This directly enables zero dead inventory. Warehousing costs plummet because you’re not storing air or obsolete cardboard. Capital is freed up for other business investments and creative projects.

Furthermore, it allows for faster reactions to packaging design updates. If a regulation changes, you simply update the digital file in the design software. The very next box off the line is compliant and complete.

Manual Prepress Slows Down Custom Packaging Design

Traditional workflows depend heavily on manual dieline creation, artwork validation, and proofing. Designers spend countless hours emailing PDF files back and forth with clients.

This creates massive bottlenecks when handling various custom packaging designs at scale. If a printer receives 50 unique orders a day, manual checking becomes impossible. Human error inevitably increases as volume rises.

Solution

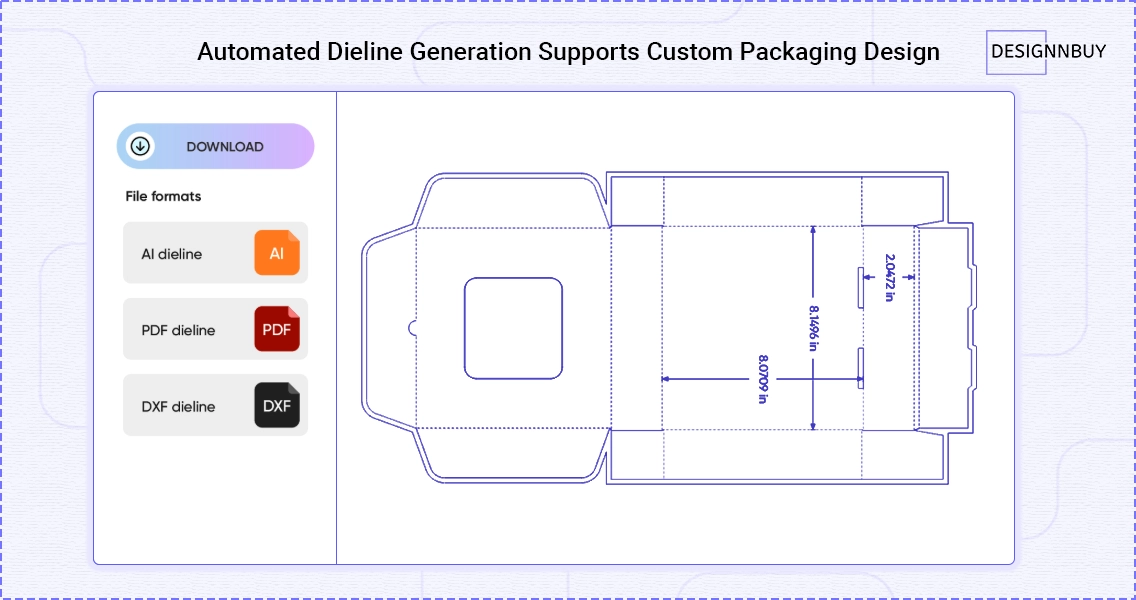

The web to pack software editor dynamically generates dielines based on box structure, dimensions, and substrate from the dielines you have integrated to the software for your customers to use. The user enters the size, and the software calculates the dieline instantly.

This ensures that the custom packaging design is structurally accurate and production ready. It removes the need for a CAD designer to manually draw every single order using tools like Adobe Illustrator. The algorithm handles the math, and the process operates in real time.

The web to pack tool generates print ready files automatically, ensuring speed without engineering compromise. You get structural accuracy across infinite variations. It guarantees reliable repeat production every time while helping teams save effort and manage complexity better.

Custom Orders Are Difficult to Scale Reliably

Without structured automation, every variant of size, material, and design increases operational dependency and risk.

Handling unique dimensions for every customer usually requires a structural engineer or experienced designer in a traditional studio setup.

This limits how many customers a business can serve. Your best talent cannot focus on innovation, explore new ideas, or work on high-value projects if they are busy drawing dielines.

Scaling becomes a personnel problem rather than a technology solution. Modern businesses need platforms that are user-friendly and suitable for both technical and non-technical users.

Solution

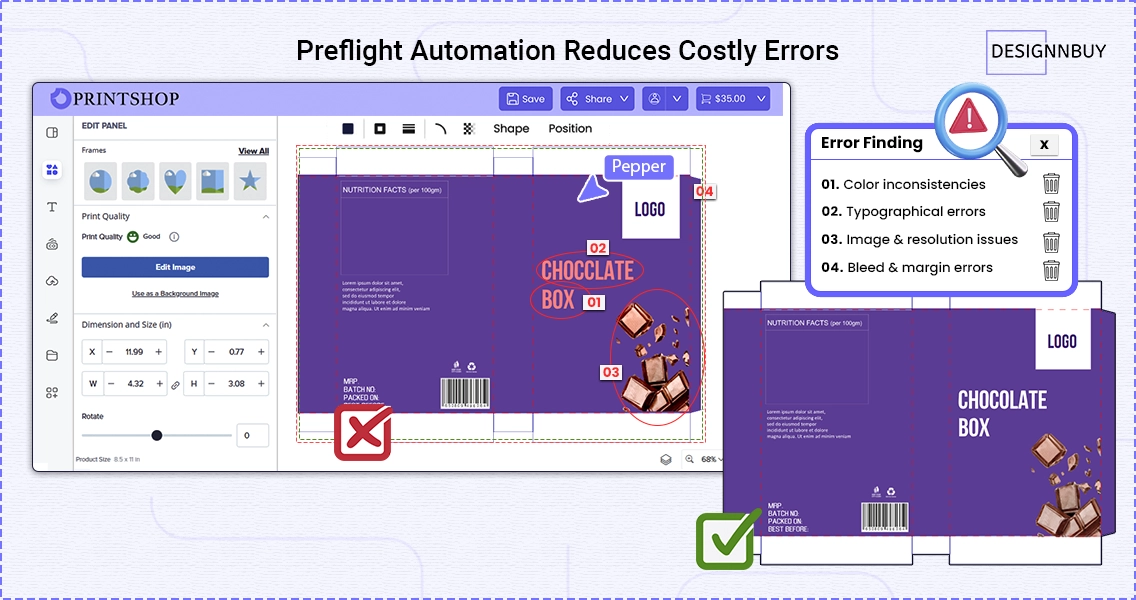

Our preflight software proofreads the artwork for bleed, resolution, and color mode automatically. This makes it act as a gatekeeper, preventing files with mistakes from entering the production line.

It also checks dieline placement, which is critical for high-quality product packaging design. The system immediately flags a logo that is too close to a fold line or incorrectly positioned images. The customer can fix it before the order is even placed.

This eliminates downstream risks and frustrated clients. It drastically reduces reprint cycles caused by file errors. Your production team receives files that are ready to print, in the correct formats, and at the right quantity—ensuring a smooth process from design to delivery.

The solution offers an intuitive interface that companies and brand teams can use without extensive training, making the entire packaging workflow more efficient.

Excessive Waste From Reprints and Misalignment

Mismatch between dielines, artwork, and finishing processes often leads to unnecessary waste.

A design might look excellent on screen but fail during the folding and gluing stage. This directly damages margins and sustainability objectives.

Every scrapped sheet includes the cost of materials, ink, machine time, and labor. Eliminating these errors is crucial for profitability and maintaining a competitive pricing structure.

Solution

Web-to-pack technology eliminates these avoidable printing errors by validating artwork and structure before the file ever reaches production.

Automated preflight checks ensure bleed, resolution, color mode, dieline placement, and fold-safe zones are correct, removing guesswork from the process and helping teams produce consistent results.

The system also simulates how the packaging will fold and finish, ensuring the printed design aligns perfectly with its physical structure. This predictive capability is suitable for both simple labels and complex boxes.

By catching alignment issues early, you avoid reprints, save materials, and protect margins. This keeps production predictable, reduces waste, and ensures every run is consistent from the first sheet to the last.

The platform helps teams streamline operations, reduce costs, and maintain quality across all packaging products—from cartons to flexible materials.

Limited Agility for Modern Brands

Brands today demand faster product launches and flexible packaging design updates. They want to react to social media trends instantly and export designs across multiple formats.

Traditional workflows cannot match this pace consistently. It can take weeks to go from a new design concept to a finished box. In the digital age, that timeline is simply too slow, and speed has become a competitive advantage.

Solution

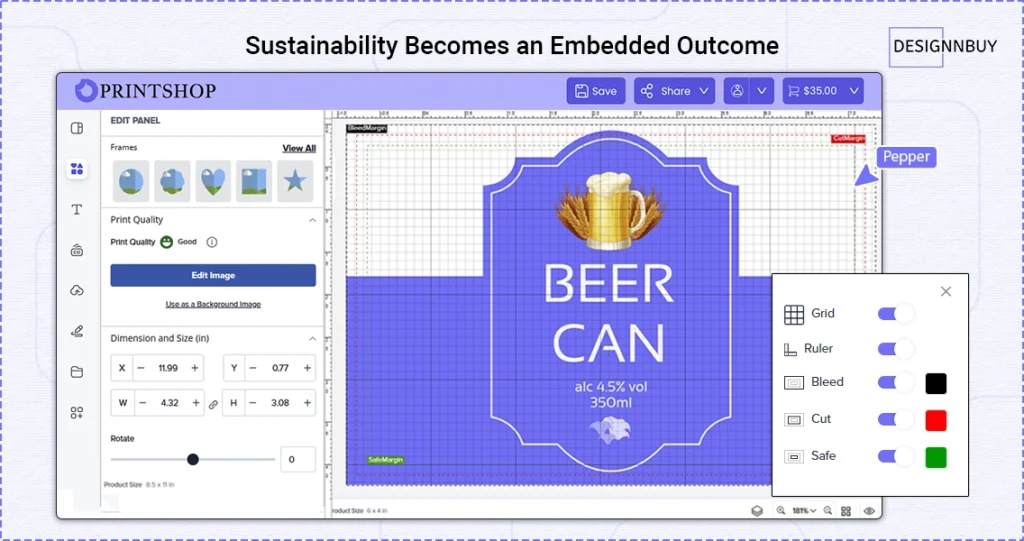

By optimizing material usage and enabling right-sized product packaging, waste is minimized. The software can nest designs efficiently to use every inch of the substrate, regardless of shape or style.

Reducing overproduction means sustainable packaging design becomes a direct operational outcome. It’s no longer just a marketing claim on a website. It’s a measurable reduction in your environmental impact that customers and companies can review.

The web to pack solution provides real-time visibility into the design and production process, allowing businesses to import assets, create mockups, and customize packaging products faster than ever before.

Teams can collaborate using templates that ensure brand consistency while still offering flexibility. The designer can work directly in the web-based studio, make adjustments, and see changes instantly without switching between multiple software applications.

Bottom Line – Why DesignNBuy’s Web-to-Pack Solution Is Built for Your Business

In my experience, packaging businesses achieve success today only when packaging design, customization, sustainability, and production efficiency move together as one system. That’s exactly what DesignNBuy’s web to pack solution is built to deliver.

Our web-to-pack software combines an advanced web-to-pack packaging design editor, automated prepress, intelligent product configuration, and seamless production integration. This single platform enables businesses to create high-impact product packaging designs, execute custom packaging designs at scale, and support sustainable packaging designs without operational chaos.

Whether you’re producing pouches, boxes, inserts, flexible packs, or even managing accessories like packaging tape, DesignNBuy‘s web-to-pack solutions give you centralized control, automation-driven accuracy, and the agility modern packaging demands.

The solution is compatible with industry-standard tools like Adobe Illustrator, supports multiple file formats including PDF files, and works seamlessly within existing packaging workflows. Users can import assets, work with templates, apply spot colors, and manage the entire design process from a user-friendly interface.

By bringing design, ordering, validation, and production into one connected workflow, our web to pack technology empowers packaging brands, printers, and converters to move faster, reduce waste, protect margins, and compete confidently in a highly dynamic global market.

The platform helps businesses save time, reduce costs, and create better packaging products—all while giving customers and internal teams the tools they need to produce exceptional results at speed.

Build Better Packaging Experiences

See how web-to-packaging solutions help overcome customization, speed, and accuracy challenges in modern packaging.

FAQs

What’s the biggest bottleneck in traditional approval processes?

File access friction. When clients have to download large PDF files, find software like Adobe Illustrator to open them, and coordinate feedback across multiple people, each step adds delay. The most successful print shops have eliminated this by using shareable links that work instantly on any device without requiring downloads. This streamlined process helps teams save time and complete projects faster.

Does automation compromise print quality or packaging strength?

Web-to-pack enables true on-demand production by shifting from “make-then-sell” to “sell-then-make.” With DesignNBuy’s solution, packaging is only produced when orders are placed, eliminating speculative bulk printing entirely. When design changes occur—whether regulatory updates or branding refresh—you simply update the digital file, and the next production run reflects those changes immediately, with zero obsolete inventory. This approach helps businesses save money and reduce waste.

Can customers design their own packaging using your web-to-pack editor, or does it require technical expertise?

DesignNBuy’s web-to-pack packaging design editor is built for both technical and non-technical users. Customers can safely personalize packaging within defined rules and templates, while the system automatically handles complex technical requirements like bleed, resolution, color modes, and dieline placement. This democratizes custom packaging design while maintaining production quality and structural integrity—no CAD expertise required. The user-friendly platform makes it easy for anyone to create professional packaging products.

How does web-to-pack software help us respond faster to market trends and customer demands?

Speed and agility are core advantages of DesignNBuy’s platform. Automated workflows compress what traditionally took 4-6 weeks into 7-10 days. When brands want to react to social media trends, launch limited editions, or test new markets, your web-to-pack system enables immediate response. Design updates happen digitally in minutes, not weeks, and production begins as soon as orders are placed—giving you and your customers the competitive edge modern markets demand. The solution helps businesses produce packaging at the speed the market requires.

File access friction. When clients have to download large PDF files, find software like Adobe Illustrator to open them, and coordinate feedback across multiple people, each step adds delay. The most successful print shops have eliminated this by using shareable links that work instantly on any device without requiring downloads. This streamlined process helps teams save time and complete projects faster.

Web-to-pack enables true on-demand production by shifting from “make-then-sell” to “sell-then-make.” With DesignNBuy’s solution, packaging is only produced when orders are placed, eliminating speculative bulk printing entirely. When design changes occur—whether regulatory updates or branding refresh—you simply update the digital file, and the next production run reflects those changes immediately, with zero obsolete inventory. This approach helps businesses save money and reduce waste.

DesignNBuy’s web-to-pack packaging design editor is built for both technical and non-technical users. Customers can safely personalize packaging within defined rules and templates, while the system automatically handles complex technical requirements like bleed, resolution, color modes, and dieline placement. This democratizes custom packaging design while maintaining production quality and structural integrity—no CAD expertise required. The user-friendly platform makes it easy for anyone to create professional packaging products.

Speed and agility are core advantages of DesignNBuy’s platform. Automated workflows compress what traditionally took 4-6 weeks into 7-10 days. When brands want to react to social media trends, launch limited editions, or test new markets, your web-to-pack system enables immediate response. Design updates happen digitally in minutes, not weeks, and production begins as soon as orders are placed—giving you and your customers the competitive edge modern markets demand. The solution helps businesses produce packaging at the speed the market requires.